Rockers Arms

We have received many inquiries about the various types of rocker arms and bearings since publishing our tech article on stainless steel rockers. Folks are asking questions about the pros and cons of the different rocker types, bearings, and materials.

Rocker material: Aluminum, Iron, Stainless/steel, Steel.

The steel rockers are the O.E.M. stock rockers which are formed (stamped) out of sheet steel.

They are the basic type of rockers which are inexpensive to produce, do the job, and last a long time in a stock engine, but expect the ratios to vary considerably. We have seen a rocker designed to be 1.5:1 as low as 1.37:1 and rarely better than 1.43:1. Up-grading to good roller rockers will improve the performance by virtue of the improved (correct) ratio. There is no adjustability in these stamped rockers which is also a drawback when trying to use a cam with much lift. They do have advantages. They are cheap and plentiful, and they are quiet. Here again, I refer to our tech article: What you need to know before you build your engine you did read it, didnt you? In it I talked about the trade-offs you will encounter when you begin to build for performance gains. One of the first things you trade-off when you modify your engine is noise and here is one of the places where you will trade quiet for performance.

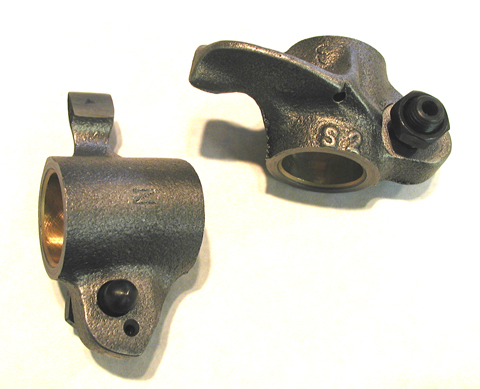

The forged iron rockers are actually an older style rocker than the stamped rocker. The forged iron units were standard equipment, adjustable and used since the beginning of time.

Note: The above photos are of the original forged iron 273 rockers that are highly modified for special oval track engines. They have, among other changes, bronze bushing and roller rocker type adjusting screws and nuts.

Note: The above photos are of the original forged iron 273 rockers that are highly modified for special oval track engines. They have, among other changes, bronze bushing and roller rocker type adjusting screws and nuts.

Once the stamping technology developed to such a point that stamped rockers could be made, about the mid-60s, the more costly iron rockers virtually disappeared. They had somewhat of a resurgence when offered by the O.E.M. manufacturers from the mid-60s to the early 70s. They were a quick solution for the solid lifter or high performance hydraulic cammed engines needing adjustability. The valve spring diameters, pressures, valve lift, rates-of-lift, and RPMs today are much more aggressive than they were 40 or 50 years ago, and, therefore, we consider the forged iron rockers unsuitable in todays engines. At one time we sold them but there were so many problems with galling that we dropped them. They have the same galling problems as the unbushed stainless steel rockers.

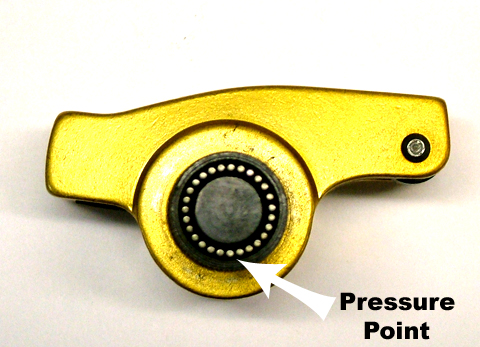

In the late 50s the O.E.M. stamped rockers started to fail from the high spring pressure with the more aggressive camshafts and higher RPMs and so-called fully rollerized rockers were developed. For the most part, we are talking Chevys here but youve got to start somewhere. The needle roller bearings were used at the trunion because of the Chevy's problem of not having full engine oil pressure at that pressure point, like Mopars do. Needle roller bearings were used because they can operate with very little oil and no pressure, although they provide no friction reduction over a plain bearing surface. Most high RPM (14000 19000RPM) race engines use full oil pressure to these high stressed areas and use no needle bearings; they utilize a plain bearing type surface. Now this can mean anything from an aluminum rocker or steel rocker to something with a special surface treatment (conditioning) to a material like a D.L.C. (diamond like carbon) coating or some similar frictionless coating on the shaft and/or the rocker. The coated or treated rockers are definitely on the high dollar end of the group but they are the most durable and highest power deliverers, because of the reduced friction and harmonics. The needle bearing rockers are a fairly cost-effective solution but they have reduced life expectancy. All the pressure and shock in the valve train is concentrated on 1 or 2 needles at the most.

The rockers only rock in a small arc of approximately 25 or 30. If the rocker or the shaft actually rotated the needles would live longer. Here again is a conundrum. The smaller needles spread the load over more needles, but they are more fragile you just cant win! Some of the roller rockers even have needle rollers in the roller at the tip of the rocker. The unit loading is very high with needle bearings. All these extra parts are just more points of potential failure.

Some of the import stainless steel rockers have a bronze bushing but these particular rockers seem to have other problems that cannot be cured with a bronze bushing. The third type is a stud mounted rocker and has the needle rollers at the trunion.

We offer this type rocker for the Magnum truck heads. As they are oiled through the push rods. With the stainless steel rockers, this question presents itself: if the stainless steel rocker arms are stiffer and stronger than aluminum (which they are) why dont the NASCAR and other pro-type race engines use them. It seems to be a problem with harmonics, vibration and cost. The aluminum rocker has some dampening qualities that the stainless steel does not enough to make the aluminum a better choice? NASCAR engine builders cant afford stainless steel rockers? Now, about that ocean front property I have for sale in Kansas!

The stock big block and L.A. small block rockers have full oil pressure to the shaft and rocker bearing area. This allows the rockers to float on a film of pressurized oil and this is an excellent way to lubricate this area. The pressurized oil comes out of the rocker shaft on the bottom where the pressure of the rocker is the greatest. For the oil to flow, the rocker must be pushing away from the shaft. Anytime there is oil pressure the rocker is floating off of the shaft similar to the main and rod bearings. In our aluminum rocker kits, we have made special provisions to make sure the oil pressure stays higher in this area and flows better than our competitors rockers. Our experience with our design has proven that a properly designed solid aluminum rocker arms, with a properly designed oil system receiving full engine oil pressure is the best choice.

We have found that our aluminum rockers with full pressure oil system work extremely well and live much longer than the needle bearing rockers. And, the more severe the application, the greater the difference in the life expectancy. The aluminum itself is a bearing material, so no bronze bushing needs to be installed. If the aluminum fails, it is not due to the lack of a bronze bushing. Under the same circumstances, the bronze would fail too. Another drawback with boring out a rocker to install a bushing or bearing is that it reduces the strength of the rocker. This problem is especially harmful in the armpit area of the small block rockers which are thin in that area to start with.

When you have a shaft spinning or rocking in a bore, one of those pieces has to be softer (lower on the hardness scale) than the other to be compatible. The situation is the same as with main and rod bearings. If you used steel rod bearings, how long would the steel on steel live? Not very long! Same with the rockers. This is why the plain forged iron or stainless steel rocker gall on their shafts so easily.

Whats the future hold for rocker arms? As mentioned above, the special coatings and processing on the shafts and/or the rocker arms will slowly be integrated into various lines of rockers. The hold-up now is the same with all new technology cost. Specially treated rocker assemblies might double or triple their cost. Note that Crane has a plain bearing in one of their Chevy rockers- expensive, yes, but durable and worth some power according to them.

The day is fast approaching when the roller tip will disappear on roller rocker arms; note the newer engines like the 5.7 Hemi, and LS-1 and LS-6 Chevys. The roller tips are a problematic area. Anything that has moving parts is subject to problems in manufacture, assembly, and/or in operation. The roller tip will be replaced by a non-moving radiused surface similar to the O.E.M. stamped or iron rockers.

If the radius is properly designed the tip will rock, not slide, across the tip of the valve similar to a rocking chair. This will provide a larger contact surface for better support and less wear on the tip of the valve. With roller rockers and very high spring pressures the narrow contact point of a roller will cause a depression in the valve tip. This problem becomes worse as the valve stem diameter gets smaller and spring pressures increase, but can be reduced with this radiused tip. This will allow the rocker design to be much smaller and lighter, allowing higher RPM with improved valve control with less spring pressure. We see both of these changes coming down the road. The old stamped or forged rockers had tip radiuses designed for low, stock lift cams. Their problems started when the cams used with them had much higher lifts and higher attendant higher spring pressures. The new rocker will use a hard radiused tip designed for extreme lifts and most likely have a coated tip along with a treated shaft. Some experiments with solid rockers with no moving parts (i.e. rollers) have shown interesting power gains, as noted above with Cranes plain bearing rockers.

As a point of interest, some information sources have condemned aluminum rockers as short-lived when compared to OEM stamped rockers. This is a very unfair comparison their environments are completely different. In the first place, the stock stamped rockers would have an extremely short life span, possibly measured in minutes, when used with high performance / racing cams and high pressure springs as some poor blokes can verify! Conversely, an aluminum roller rocker with stock cam and attendant low pressure springs might easily exceed the OEM stamped rockers life. This is not an apples to apples comparison.

Designs and technology march on. Dont get caught in the 60s mindset! |