|

|

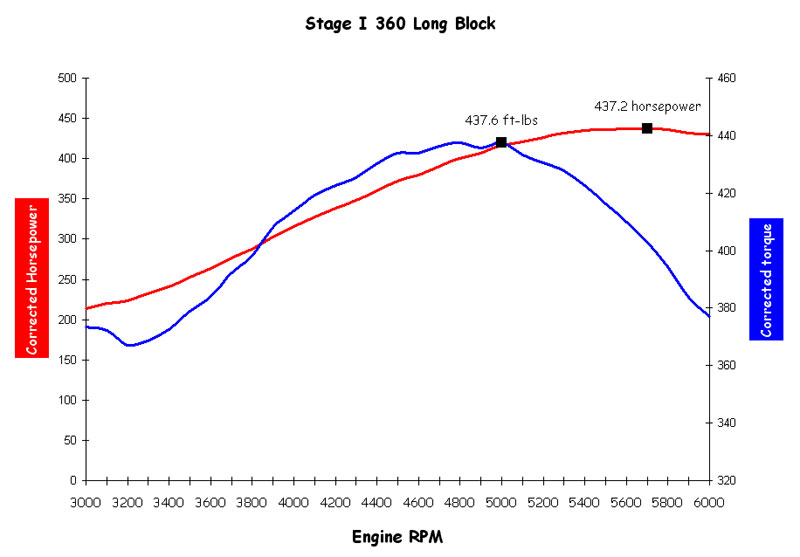

#2---360 Dyno Test (Feb 2000)

437.2 HP & 437.6 ft./lbs | 2/26/2021 |

Stage I 360ci dyno test

This is our base Hot Street engine using iron LA heads, a hydraulic camshaft and pump premium gasoline. It can be upgraded to about 500 HP with cylinder head, camshaft, compression ratio and intake manifold changes, yet still remain on pump premium gasoline. It can also be downgraded to under 400 HP output. We list this engine as our Stage I 360 long block part number 360LONG-S1 and call it Brett's combination because it was designed for our lead porting man's 1985 1/2 ton pickup. This is our base Hot Street engine using iron LA heads, a hydraulic camshaft and pump premium gasoline. It can be upgraded to about 500 HP with cylinder head, camshaft, compression ratio and intake manifold changes, yet still remain on pump premium gasoline. It can also be downgraded to under 400 HP output. We list this engine as our Stage I 360 long block part number 360LONG-S1 and call it Brett's combination because it was designed for our lead porting man's 1985 1/2 ton pickup.

Components:

The short block consists of our standard racing block preparation. This engine was built 3 years ago and we used the stock type 360 crankshaft and connecting rods that were race prepared (ARP bolts, straightened, aligned, etc). Currently our short block preparation uses forged I-Beam connecting rods. These rods are stronger, lighter and use full floating wrist pins. The pistons were modified Keith Black units.

The cylinder heads were ported to our Stage II level of the time. Our current Stage II heads flow better in the mid-lift ranges and produce more power. These were '596 castings which are garden variety late 1970's heads.

The HE3038AL hydraulic camshaft was chosen because it is nearly 4 sizes smaller than the Mopar Performance camshaft provided in the 360ci/380HP crate engine. The HE3038AL provided more power, more torque, and better street manners. We used our very trick HUG 6442 ProGear timing set with hardened sprockets. These timing sets are like the Energizer bunny, they keep going and going. We used our optional, corrected, 1.6:1 aluminum rockers on this combination instead of the corrected 1.5:1 iron rockers found on the standard 360 long block we offer. These aluminum rockers increased the torque and power throughout the RPM range as compared to the factory 1.4:1 stamped pieces. Our 1.6:1 rockers also don't roll off the tip of the valve like the ones you buy from the Chevy place.

The owner of this combination provided a EDE 5091 (Edelbrock Torker II intake) due to hood clearance problems. We reworked the Torker II, but one of our reworked EDE 7193 (Edelbrock Performer RPM intake) would probably take this engine over 450 HP!

Dyno pulls and conclusion:

All of the dyno testing was done with an Edelbrock 750 CFM carburetor that needed only slight jetting changes. We tested with 1 5/8" headers and TTI stepped 1 5/8" - 1 3/4" primary headers. The TTI headers and some of the pipes had to be modified to fit the truck as they were designed to fit a car chassis and we had trouble mounting them on the dyno. The collectors would not clear the instrument pedestal (see the photo below) so we were unable to vent the exhaust properly during testing. This caused the dyno cell to fill with exhaust gas and contaminate the intake charge, somewhat like piping the exhaust into the carburetor. None the less, we tried to get some indication of how much the stepped headers would help, if any.

We made a few pulls but the fumes in the control room got to be unbearable. We tried opening the door to the dyno cell and holding our breath to get some numbers. We actually saw more power this way than any other run, but the conditions were too poor to do any carburetor or ignition tuning to compliment the stepped headers. From what little "testing" we tried, we would say the low end power was on par with the 1 5/8" pipes and the upper RPM power was going to be considerably greater. We would definitely suggest the stepped headers in a very Hot Street or Street/Strip combination that needs some low end for normal driving.

As you can see from the dyno sheet, the 375 ft-lbs of torque or more from 3000 to 6000 RPM, we design our combinations to be very torquey. Notice the very smooth, incremental increases and decreases. The horsepower curve was very flat and wide with a variance of only 6 HP from 5300 RPM to 6000 RPM....very smooth. This engine could handle lots more camshaft without the need for larger port heads or more compression ratio. If you are willing to give up some of the torque, we can build this combination with a larger camshaft (hydraulic or solid) and move the horsepower into the 465 range.

Final results:

437.2 Horsepower

437.6 ft-lbs torque

Click here to view a larger image of Dyno sheet

Click here to view a larger image of Dyno sheet

|

|

| | Home | Phone: 309-745-9558 | Email: information@hughesengines.com |